Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: ZT-008 | Place of Origin: China |

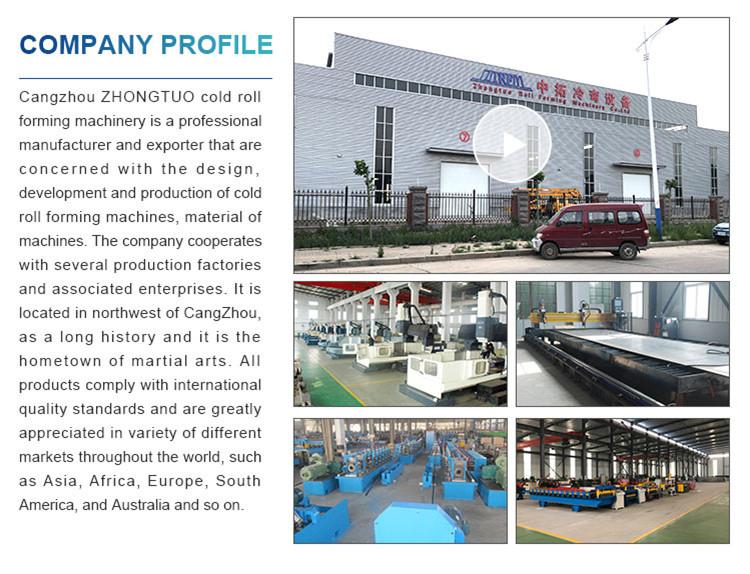

Automatic steel ceil t bar roll forming machine ceiling system t grid tee forming machine crosst wall making machine

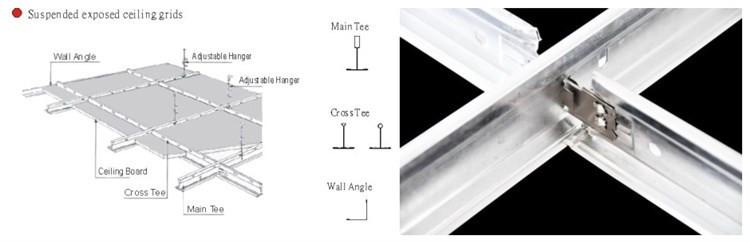

Automatic steel ceil t bar roll forming machine ceiling system t grid tee forming machine crosst wall making machine is for making the t grid use for the ceiling.

Usually the t grid have two types:main T bar and cross T bar

Zhongtuo automatic high speed interchangeable steel T bar roll forming machine could be used to make Main T and cross T.

Brief features:

1.CE/ISO certificate products.

2. Profile could be customized

3.Stable working and easy operation

Main T bar: equiped with inverter motor, producing in line speed: 30M per minute. Hydraulic automatic punching and cutting machine linked with main forming machine,punching and cutting automatically. Two heads and middle holes are punched and cut-off at the same time after forming.

Cross T bar: equiped with both inverter and servo motor producing in line speed: 30M per minute. Main machine with constant speed,it is traced by the servo trace system, automatic tracing the speed of the main

machine, punching and cutting automatically. Two heads and middle hole are punched and cut-off at the same time after forming.

We also have machines for producing purlin of C shape, W shape, M shape and others. Please find those machines in related products.

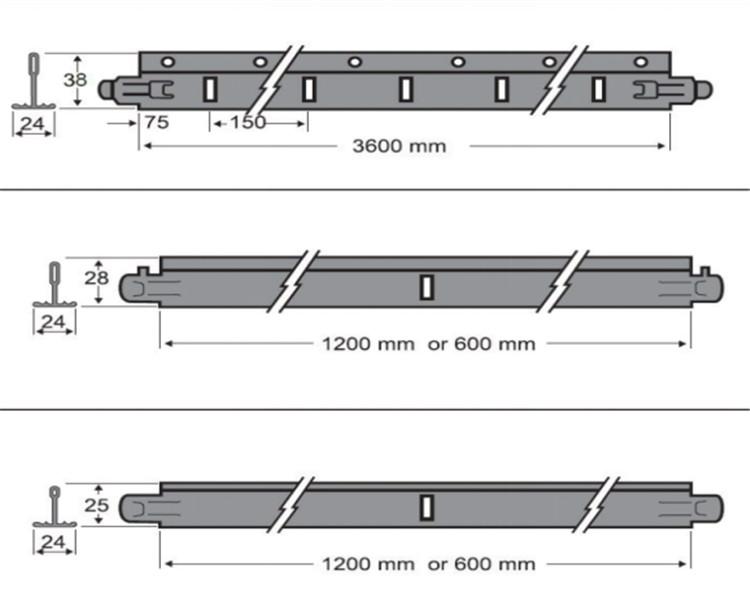

Check profiles of Main T bar and cross T bar:

Main specifications of T-Bar roll forming machine:

Automatic steel ceil t bar roll forming machine ceiling system t grid tee forming machine crosst wall making machine

Automatic steel ceil t bar roll forming machine ceiling system t grid tee forming machine crosst wall making machine is for making the t grid use for the ceiling.

Usually the t grid have two types:main T bar and cross T bar

Zhongtuo automatic high speed interchangeable steel T bar roll forming machine could be used to make Main T and cross T.

Brief features:

1.CE/ISO certificate products.

2. Profile could be customized

3.Stable working and easy operation

Main T bar: equiped with inverter motor, producing in line speed: 30M per minute. Hydraulic automatic punching and cutting machine linked with main forming machine,punching and cutting automatically. Two heads and middle holes are punched and cut-off at the same time after forming.

Cross T bar: equiped with both inverter and servo motor producing in line speed: 30M per minute. Main machine with constant speed,it is traced by the servo trace system, automatic tracing the speed of the main

machine, punching and cutting automatically. Two heads and middle hole are punched and cut-off at the same time after forming.

We also have machines for producing purlin of C shape, W shape, M shape and others. Please find those machines in related products.

Check profiles of Main T bar and cross T bar:

Main specifications of T-Bar roll forming machine:

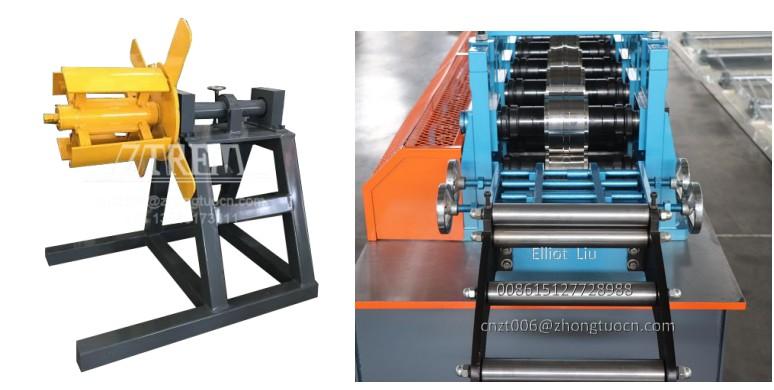

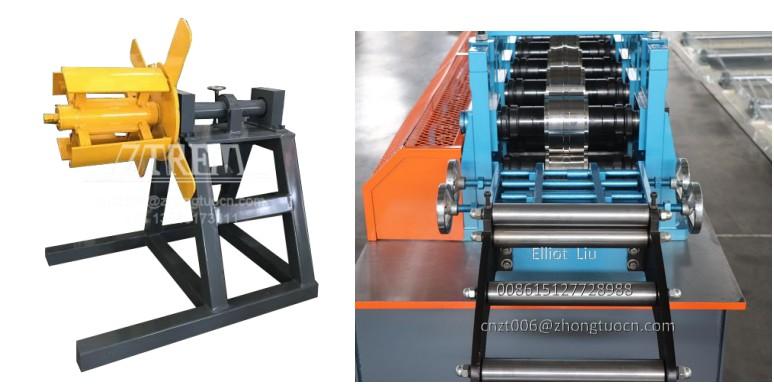

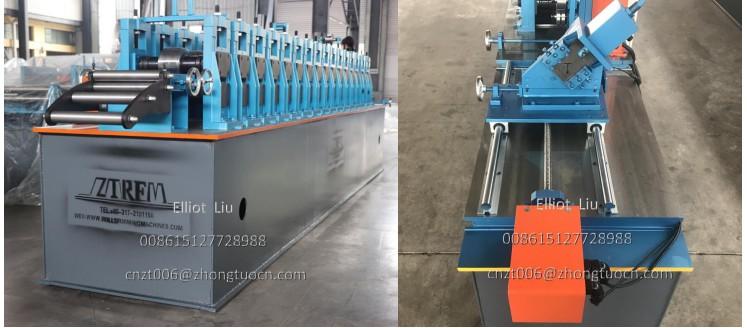

manual decoiler entry beach

Roll forming device hydraulic cutting device

|

Decoiler |

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system Loading capacity: 1.5T Uncoiling width: 300mm Inner diameter: 450-550mm |

|

Entry Beach |

Usage: Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. Feature : Ensure stability , precision and lifetime. |

|

Main Roll Forming System |

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission( the first and the last roller, the down roller should be attached with the upper one with the gear drive.), roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Length of the main part: about 3500*800*1400 Weight of main part: 3 tons Voltage : 380V/50HZ3Phase (as customer’s request) Roller fixer : Guide column Frame : middle plate welded Memorial arch frame type Frame thickness:25mm Drive mode: gear Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: 40mm Number of rollers : 16 rollers Main power: 3kw Cycloidal planetary gear speed reducer) Noted: different sizes will be produced by adjusting the spacers by hand. |

|

Shearing Mechanism |

Function : Automatic cutting controlled by PLC It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Gcr12MoV quenched Power supply : hydraulic power Frame : Pillar style with rack & pinion system Stroke switch : non-contact photoelectric switch Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine. |

|

Electric Control System:

|

1.Adopted PLC , transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2.Other electric element are Delta 3.Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety. |

manual decoiler entry beach

Roll forming device hydraulic cutting device

|

Decoiler |

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system Loading capacity: 1.5T Uncoiling width: 300mm Inner diameter: 450-550mm |

|

Entry Beach |

Usage: Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. Feature : Ensure stability , precision and lifetime. |

|

Main Roll Forming System |

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission( the first and the last roller, the down roller should be attached with the upper one with the gear drive.), roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Length of the main part: about 3500*800*1400 Weight of main part: 3 tons Voltage : 380V/50HZ3Phase (as customer’s request) Roller fixer : Guide column Frame : middle plate welded Memorial arch frame type Frame thickness:25mm Drive mode: gear Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: 40mm Number of rollers : 16 rollers Main power: 3kw Cycloidal planetary gear speed reducer) Noted: different sizes will be produced by adjusting the spacers by hand. |

|

Shearing Mechanism |

Function : Automatic cutting controlled by PLC It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Gcr12MoV quenched Power supply : hydraulic power Frame : Pillar style with rack & pinion system Stroke switch : non-contact photoelectric switch Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine. |

|

Electric Control System:

|

1.Adopted PLC , transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2.Other electric element are Delta 3.Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety. |

![]()